PLATE SPECIFICATION

WHY USE AN INJECTED HDPE PLATE?

safety

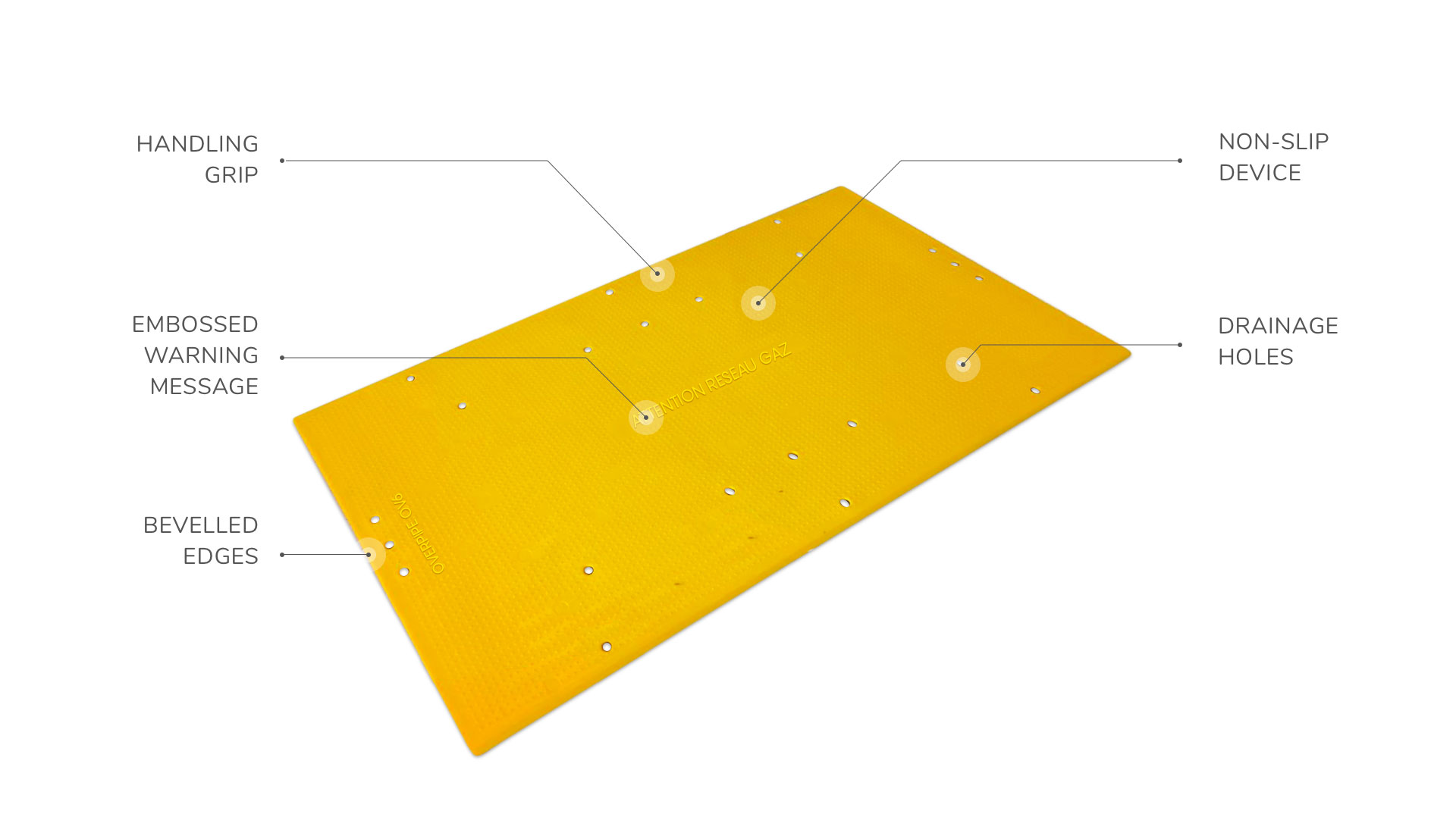

Improved safety thanks to non-slip surface and bevelled edges. They are covered on both sides with a non-slip surface, to make them easier to handle and avoid slips, trips and falls.

The plates form a barrier against impact from the bucket of a 32-tonne excavator.

ERGONOMICS

INNOVATIVE DESIGN

During the moulding process, holes are incorporated into the plates to aid water drainage, prevent pockets of gas forming in the case of a gas leak and to avoid disrupting cathodic protection signals.

APPEARANCE

INSPECTION

PLATE SPECIFICATION:

DETAILS

To avoid the risk of slips, trips and falls, OVERPIPE plates have a non-slip system on both sides, formed during the moulding process. This is to ensure the safety of personnel during the handling and installation of the plates. It is also designed to prevent ground movement around the plates.

The maximum weight of the OVERPIPE plates is 50 kilos, to allow its safe handling by two people.

OVERPIPE plates have bevelled edges for better handling.

GEOMETRIC CHARACTERISTICS

The thickness of the OVERPIPE plate is 15mm.

The OVERPIPE plates are designed to allow the circulation of water, the electrical flow and the stability of the ground. The drainage holes have a diameter of 30mm and are distributed uniformly over the plate without impinging on the embossed warning message. The holes are made during the manufacturing process, without altering the mechanical strength properties of the plate.

MECHANICAL CHARACTERISTICS

MATERIAL CHARACTERISTICS

The colour is yellow within the range RAL 1021 or RAL 1023. The appearance of the plate is uniform in colour and appearance. Colour can be amended to suit requirements.

WHY USE WARNING MESH?

MAJOR INNOVATION

A major innovation for safety of underground networks, covering:

- High, medium and low-pressure pipelines

- Electricity cables

- Fibre/telecoms cables

- Any other underground infrastructure that requires protection

- 50-year life span and reusable/recyclable

DESCRIPTION

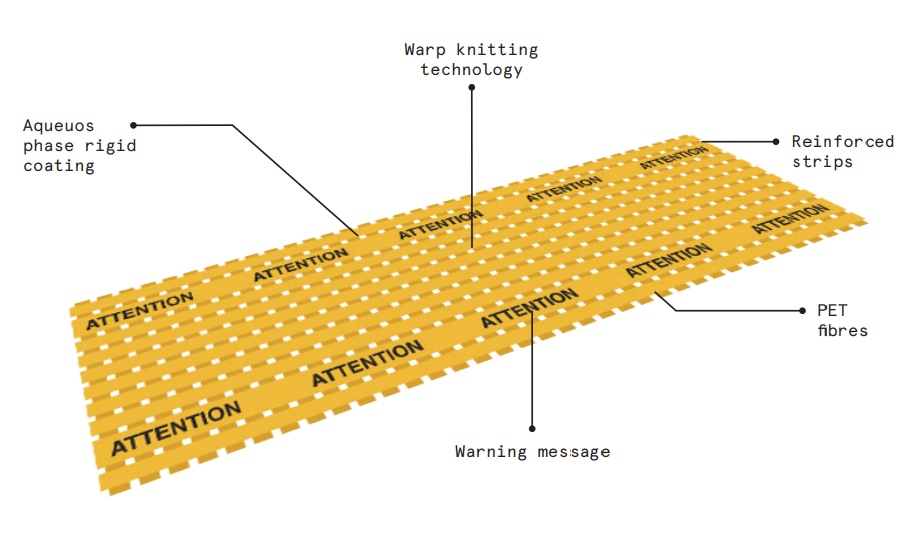

The OVERPIPE warning mesh with high elastic resistance is a geotextile composed of synthetic PET fibres with an aqueous phase coating.

- If snagged by the bucket of a mechanical excavator, it can be raised 1m above the ground without tearing

- Withstands impact from an 18-tonne excavator

- Coloured to provide effective warning signals

- Reinforced strips on the edges increase the resistance against lateral impact

- The production method of warp knitting serves to reinforce the connections between warp and weft threads

- 50-year life span and reusable/recyclable

safety

A major innovation for safety of underground networks, covering:

- High, medium and low-pressure pipelines

- Electricity cables

- Fibre/telecoms cables

- Any other underground infrastructure that requires protection

MESH SPECIFICATION:

RESISTANCE

INSTALLATION

WARNING MESSAGE

Fully customisable in colour and warning messages to correspond to the nature of the buried asset.

ENVIRONMENT

ADDRESS

OVERPIPEUK

The Estates Office,

Norman Court,

Ivanhoe Business Park,

Ashby-de-la-Zouch

LE65 2UZ

CONTACT

Sasha Dwyer

T: 0808 175 3312

enquiries@overpipeuk.com